Sweep to see the phone side

Hangzhou Fuyang Hengshan Composite Materials Co., Ltd.

Global service:+86 (0)18758868805(WeChat/Whatsapp/Imo)

Telephone:+86 0571-63253751

Fax:+86 0571-63253752

Email:shina@fyfhcl.cn jack@fyfhcl.cn

Adress:No.118 ZhangDiShang,ChangLong Village,XinDeng Town,FuYang District,Hangzhou City,Zhejiang,China

Global service:+86-18758868805

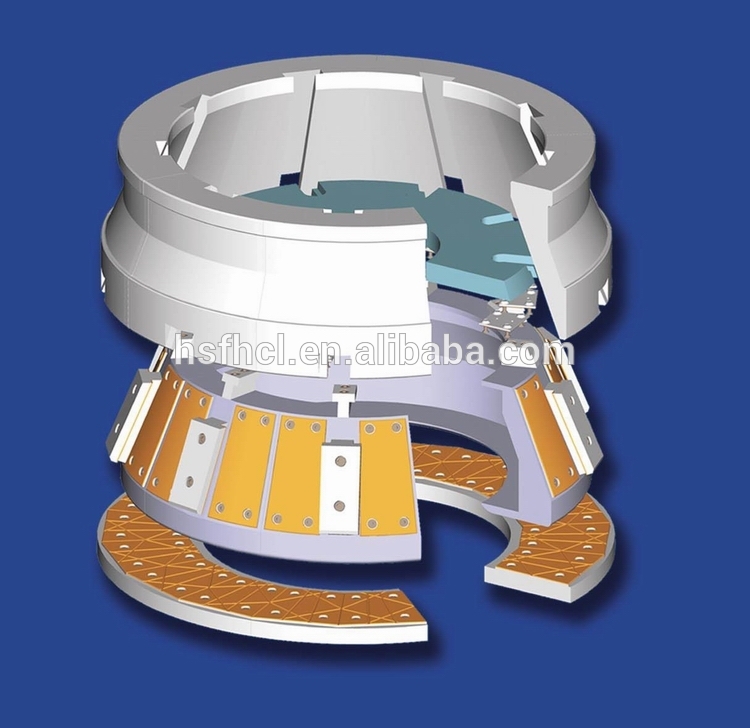

wear plate for tire segment mould

Description

We are offering to our clients a wide range of Segmented Mold Slide Plate. Graphite impregnated bronze metal used for wear plates in segmented molds (un-greased)

DEVA Metal is a range of high performance, self-lubricating bearing materials. The DEVA Metal systems are based on three metal alloy types: Bronze, iron an nickel, using powder technology and each containing dry solid lubricant, most commonly graphite. The percentage type and form of solid lubricant is determined by the bearing application and operating requirements. These bearings are capable of operating at highly elevated temperatures and in aggressive environments.

The selflubricating composite sliding material is manufactured by using a continuous hotrolling sintering technology. This manufacturing process guarantees, unlike other sintering methods, an all-over and reliable contact of the sintering layer to the steel backing material. This increases the reliability and the service lifetime of the sliding plates significantly.

Packaging & Delivery

Packaging Detail: Export standard

Delivery Detail: 20-40 days

Specifications:

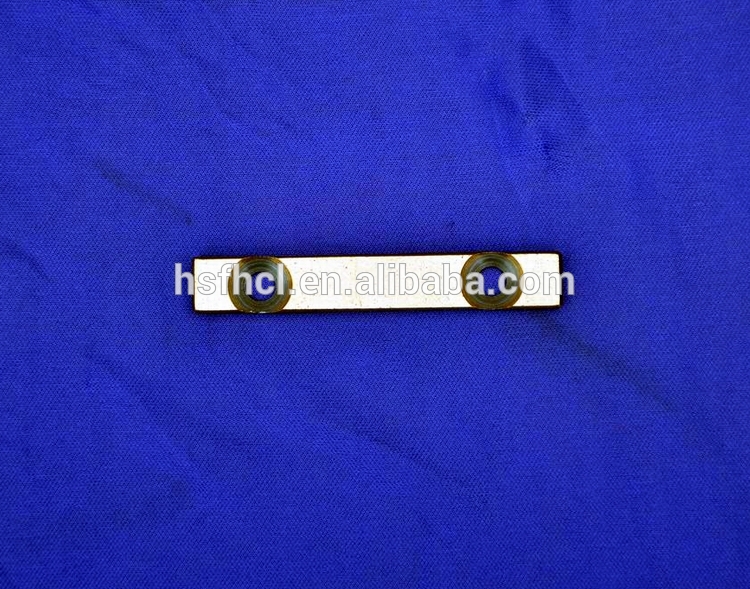

1. metal sliding plate for tyre mold

2. Advanced performance for low speed and high load

3. Long service life,cost effectiv

Product Name:

metal sliding plate for tyre mold

Raw Materials:

1. Bronze layer 0.50-10 mm thickness

2. Steel plate layer 3.0-30mm thickness

Feature:

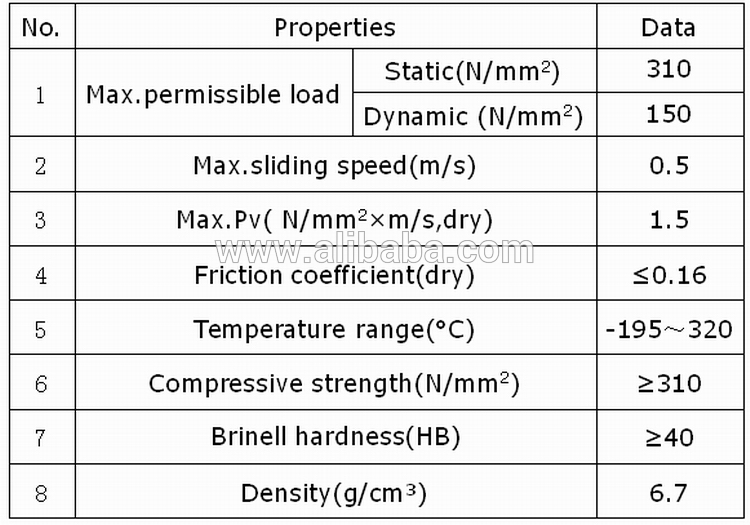

1. Max Stillness Load no less than 310 Mpa

2. Temperature: -195℃-+310℃

3. Friction Coefficient: Dry Friction: 0.05-0.2

4. Maxi linear speed: 0.5m/s

5. Hardness of the bronze layer: no less than HB45

Application:

Segmented containers and molds

• plain sliding plates for top and bottom plates

• conical formed or machinable sliding plates for

actuating rings and segments

• guiding elements (T- or dovetail guidance)

Tire heaters with segmented molds

• guide plates for axial movement of segments

• conical plates

• sliding bushes for tilting, actuating and clamping

mechanisms

Processing of Bimetal plate:

Steel plate – overspread bronze powder – sinter – machining – finishing – checking - packing

QMS:

ISO9001:2008

Advantage:

1. 20 years in making advanced composite materials

2. Great strength in design and developing advanced materials.

Corporate Clients:

Domestic customers:ShanDong Himile,GuangDong Greatoo,Tianyang mold,

Anhui WideWay,ZhongCe Rubber ,LingLong Tire ,Jinyu Tires ,Qindao DoubleStar

Foreign customers:Kara Gostar,PNEUFORM,ROSTAN Tiremolds,Pirelli(China),

Hankook, Cooper

Warmly welcome to visit our factory at your convenient time!

We will do our best to cooperate with you!